-

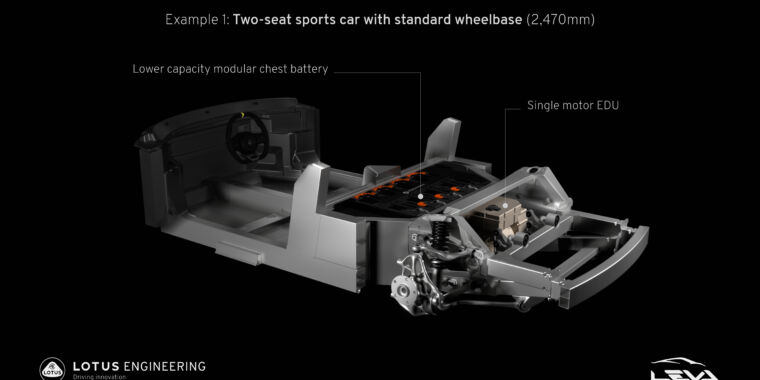

Lotus Cars is developing a lightweight electric vehicle architecture for sports cars. It uses a die-cast rear subframe that packages the drive unit. In the case of two-seater vehicles, the battery pack is located behind the passenger compartment.

-

This architecture can also create larger two-seaters with a larger center battery pack. In this application, the rear subframe contains a twin-engine electric drive unit.

-

For EV sports cars with small rear seats (known as 2 + 2s), Lotus will use a more conventional skateboard layout for the battery.

Of all the automakers who are making the transition from internal combustion engines to electric drives, only a few interest me as much as Lotus. That’s partly because I first became a car nerd after discovering the Lotus Seven. But it’s also because light weight has always been a core attribute of Lotus, and while electric vehicles have a lot going for it, they’re typically not “light”.

This would be insignificant until recently, as the small British sports car manufacturer did not have the resources to consider switching to electric. But in 2017 Lotus was bought by Geely, also owner of a freshly revitalized Volvo. As is the case with Geely, Lotus has received some much-needed investment and has been hired to work on electrification.

In April of this year, Lotus announced that its plans now include four new platforms, three of which are fully electric. This week we got a glimpse of the company’s way of thinking about electric vehicles when it released some details on its lightweight electric vehicle architecture (or “Project LEVA” in Lotus language). The key is a newly developed rear subframe that is much lighter than that of the V6-powered Emira (unveiled in July as the last internal combustion engine-powered Lotus).

The rear subframe is made from die-cast aluminum and cleverly supports multiple types of powertrain layouts. There’s the conventional skateboard approach, where a large battery plate fills the floor of the car between the axles, like basically every battery EV sold today. Lotus says that in this configuration it can build 2 + 2s with wheelbases of at least 104.3 inches (2,650 mm), with 66.4 kWh battery packs and either a single motor drive with a maximum output of 470 hp (350 kW) or a Double motor drive unit with a maximum of 872 HP (650 kW).

A skateboard isn’t always the answer

But the skateboard layout is not ideal for purely two-seater sports cars. In these applications, a lower ride height and a lower overall height of the vehicle are important. Instead of laying the cockpit on a large battery plate, Lotus will use what is known as a “chest” layout.

Here the battery pack is mounted in the middle, like the engine in one of the current Lotus cars. (This is the same powertrain layout that Porsche used for the Mission R concept, and it’s also used by most of those Unobtanium electric hypercars with phone number price tags.) advertising

Lotus says center mounting the battery leads to two possible layouts. For the smallest and lightest electric sports car, this means a wheelbase of at least 97.2 inches (2,470 mm); for the context, a Lotus Elise has a wheelbase of 90.6 inches (2,300 mm). These small electric vehicles would carry a 66.4 kWh package and use a single electric propulsion unit with up to 470 horsepower.

For larger two-seater sports cars (think Lotus Esprit rather than Lotus Elise), the wheelbase can be extended to at least 104.3 inches. These cars would have the twin-engine drive and a 99.6 kWh battery.

Richard Rackham, head of vehicle concepts at Lotus and lead engineer on the LEVA project, said:

Project LEVA is as revolutionary today as the Elise architecture was in 1996. In the true Lotus spirit, significant weight savings have been achieved across the board, with the focus on ultimate performance, efficiency and safety from the start – for example by using the vehicle structure as a battery housing , with integrated EDU, elimination of subframes and optimization of multi-link suspension components.

Unfortunately we have to wait a little longer for the first light Lotus EVs, which are not expected until 2026. But we may see the architecture being used by other OEMs much sooner – Lotus is going over it. offer the Lotus engineering consultancy to third parties.

Offer picture from Lotus Cars